Quantity Assurance

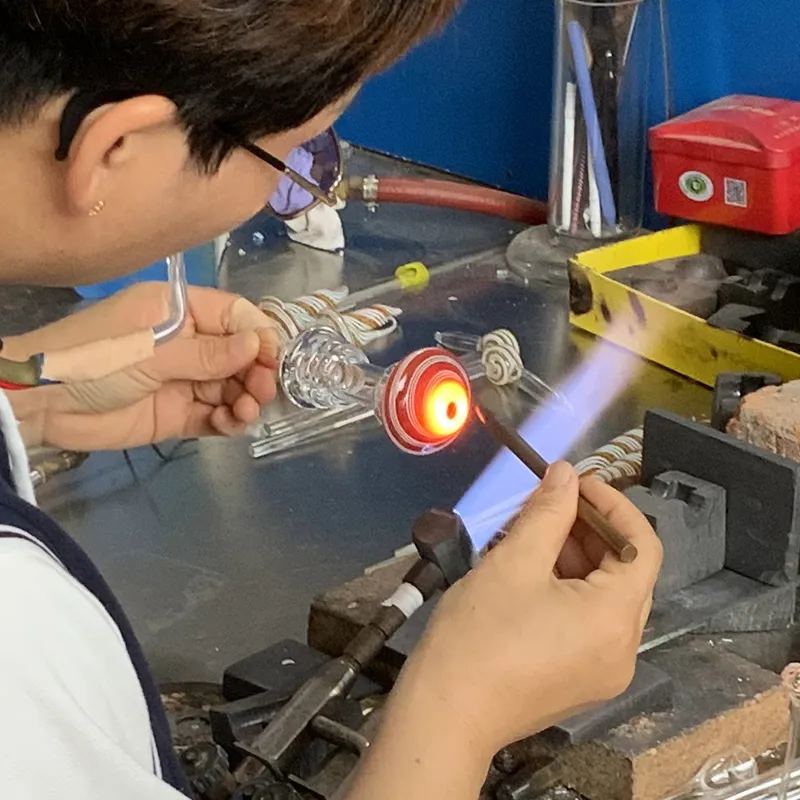

High thickness clear borosilicate glass with 10 years+ making techniques.

Upgrade your smoke shop’s water pipes and bongs with the EG Glass collection.

We craft every single pipe using thick, heat-resistant borosilicate glass. This durable material resists cracking and is easy to clean, significantly reducing after-sales issues.

We offer these high-quality pieces at factory-direct B2B prices. By skipping the middleman, you get better margins on every sale. We have all the trending models in stock and ready to ship.

EG Glass is a dedicated manufacturer of glass bongs and accessories serving wholesalers and smoke shops worldwide. We combine traditional hand-blown artistry with modern precision machinery. This approach guarantees high production output and consistent inventory stability.

Whether your customers are looking for daily drivers or showpiece rigs, our catalog covers every demand:

Beaker Bongs: The reliable, stable classic that every shop needs in stock.

Straight Tubes: Sleek, traditional designs for instant, direct hits.

Recyclers: Scientific glass engineered for superior filtration and smooth concentrate flavor.

EG Sandblasted Relief Beakers: Our signature artistic line featuring unique, textured designs that stand out on the shelf.

Ultra Thick Series: Heavy-duty heavyweight glass built for maximum durability and premium feel.

Browse our sub-categories below to find high-margin glass that keeps your customers coming back. Contact us to see exclusive wholesale pricing.

Our facility is located in Hebei, China, the core of the glass industry. We benefit from immediate access to raw materials and a complete supply chain. This advantage allows us to guarantee fast production and short lead times.

EG Glass offers robust OEM and ODM services for brands looking to differentiate themselves.

To guarantee premium quality, every product undergoes a rigorous manufacturing workflow:

EG Glass supports its manufacturing hub with a strategic 5,000㎡ warehouse in Dongguan.

We offer a comprehensive range of wholesale glass water pipes to suit every smoke shop’s needs. Our catalog includes classic Beaker Bongs for stability, sleek Straight Tubes for direct hits, scientific Recyclers for superior filtration, and our exclusive Sandblasted Relief and Ultra Thick Series for premium durability.

Yes, we specialize in OEM and ODM services. We can customize water pipes with your brand’s specific logos, decals, color accents, and tailored packaging. From initial design and sampling to mass production, we help you build your private label identity.

All our water pipes are crafted from high-grade borosilicate glass, known for its exceptional clarity and heat resistance. Every piece undergoes a rigorous annealing process in our kilns to remove internal stress, ensuring maximum durability and resistance to cracks.

We offer fast and reliable shipping options through our integrated logistics network. Orders can reach customers in the U.S. in as little as 10 days. Our 5,000㎡ warehouse stocks popular items for immediate dispatch, allowing for efficient fulfillment of mixed orders.

| Key Metric | Details |

| Location | Hebei, China (Core Glass Manufacturing Zone) |

| Facility Scale | 10+ Workshops with Modern Processing Lines |

| Monthly Output | Up to 10 Full Containers (40HQ) per month |

| Lead Time | 20–30 Days (Fast turnaround for bulk orders) |

| MOQ | Flexible (Supports mixed models & small batches) |

| Supply Stability | Reserved inventory for recurring large-scale partners |

| Example Scenario | Order 1x 40HQ Container $\rightarrow$ Production complete in ~3 weeks |

Here is the 5-step quality assurance process presented as a concise checklist, incorporating your specific requirements for technical explanations:

We implement a strict 5-Step Quality Assurance Process:

Material Certification: We strictly verify all raw glass quality before production.

Hand Shaping: Skilled artisans precisely mold each piece by hand.

Kiln Annealing (eliminating internal stress): High-temperature treatment significantly increases durability.

Surface Finishing: We apply professional polishing or sandblasting for a smooth touch.

100% Final Inspection: We check every unit for shape, clarity, and joint fit before packaging.