At EG Glass, we understand that packaging is as important as production — especially when dealing with hand-blown glassware. Every piece leaving our factory represents our brand and your business. That’s why we’ve built a clear, export-grade packaging system to keep your order safe from our warehouse to your shop floor.

Our goal is simple: make sure every item arrives intact, clean, and ready to sell.

1. Our Standard Packaging Principles

Reasonable Carton Size

Each box is sized according to the product’s shape and quantity — never too large or too tight. All cartons are designed to fit safely in shipping containers, with total gross weight kept under 25 kg for easy handling.

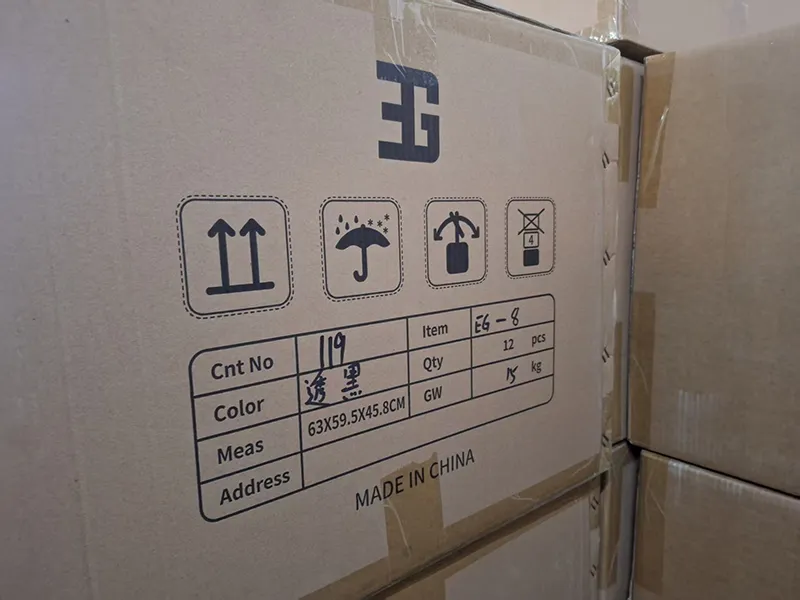

Clear Labelling and Identification

Every carton carries essential information:

- Product name, model, and quantity

- Batch number and weight

- Destination or customer code

- Country of origin: Made in China

These details make customs checks, stock management, and after-sales tracking easier.

Strong and Reliable Structure

We only use five-layer export-grade cartons that can handle pressure, stacking, and long-distance vibration. Each carton is securely sealed with high-strength tape and inspected before loading.

Handling and Safety Markings

Every box carries standard international symbols:

Fragile, Keep Dry, This Side Up, and Handle With Care — applied on both sides for visibility.

Moisture and Water Protection (If Required)

For sea freight or humid destinations, cartons are film-wrapped or waterproof-treated to prevent moisture damage.

2. Inside the Box: Layered Protection for Every Product

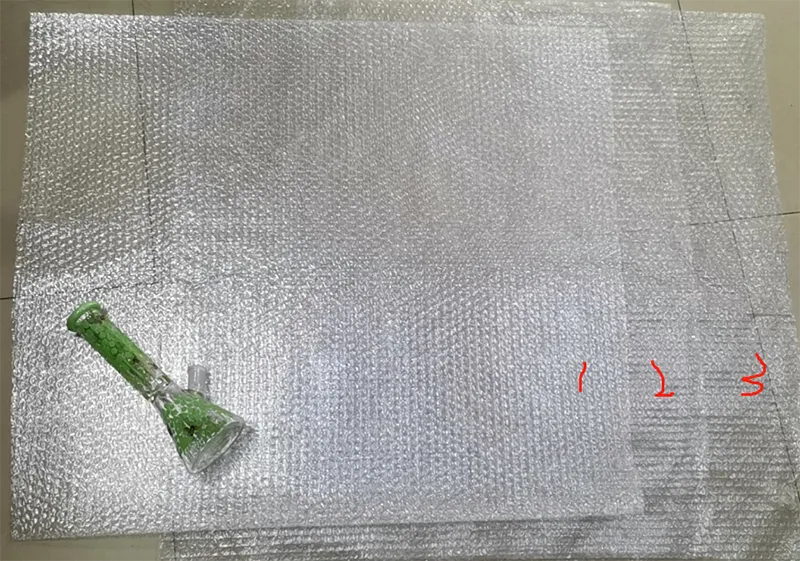

Layered Bubble Wrap

Each item is wrapped in two to three layers of bubble film.

Accessories are packed separately before being combined with the main product.

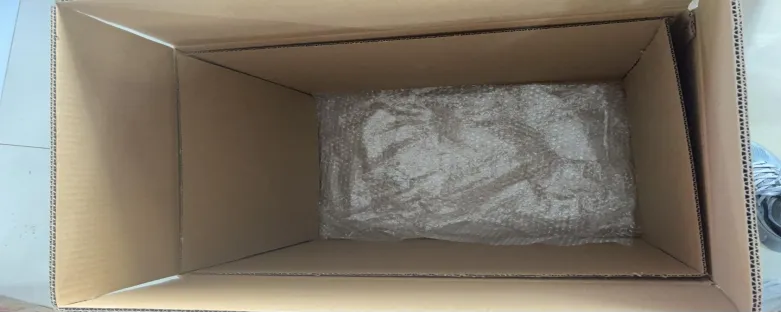

Cushioning and Structural Support

- Thick bubble sheets line the bottom of every box.

- Cardboard dividers reinforce all four sides.

- Empty gaps are filled with bubble wrap to avoid movement.

- Each layer of products is separated by another protective layer.

This ensures that no piece touches another during transport.

Sealing and Final Touch

Once filled, the top layer is covered with bubble wrap and a divider board before sealing. Products are bound with tape or rubber bands to prevent internal shifting.

3. Labelling, Barcoding & Set Packaging

Every carton must have two identical labels, one on each side, printed in advance for each shipment.

We use two barcode sticker sizes — 40×30 mm and 30×20 mm — depending on product size.

For products with special materials such as silicone or painted finishes, stickers are applied to poly bags or hang tags to prevent glue marks.

If your order includes display boxes or set packaging, we apply a unified barcode for the entire set, following your retail or inventory system.

4. Palletising & Container Loading

Our cartons are neatly stacked and palletised before container loading:

Loading layout is planned to maximise container space while preventing box compression.

One pallet usually holds around 20 cartons (four layers), depending on carton size.

Stretch film is tightly wrapped to stabilise the pallet.

5. Final Quality Check Before Dispatch

Before every container leaves our facility, our QC team performs a final inspection checklist:

- Carton integrity and sealing

- Correct labels and barcodes

- Clean, moisture-proof packaging

- Photo documentation before container sealing

This final step ensures your order meets our export standards and protects your brand reputation.

6. Why Retailers Trust EG Glass

From handmade craftsmanship to secure packaging, every step reflects our promise — Only Best Make Premium.

Retailers and distributors worldwide rely on EG Glass for consistent quality, safe delivery, and professional export handling.

If you want to see how we package your products before shipping, we can provide pre-shipment photos or videos upon request.

7. FAQs About EG Glass Packaging

How do you ensure fragile glass items arrive safely?

Through layered bubble wrapping, reinforced cartons, and strict inspection before loading.

Can you send photos before shipment?

Absolutely. We take packaging photos for every container and can share them on request.

What is the average packaging and loading time?

Depending on order size, 15–30 days, including production and quality checks.

Every EG Glass order reflects years of experience in both glass artistry and export handling.

From double bubble wrapping to five-layer export cartons, we package every piece with precision and care.

Whether you’re a smoke-shop owner or wholesale distributor, you can rest assured your glassware will arrive in perfect condition — ready to display, ready to sell.