10+ glassblowing workshops with skilled artisans

Home / About EG Glass / Supply Capability

Supply Capability

At EG Glass, our manufacturing and supply capability forms the backbone of our success. From raw material selection to international shipping, every stage is designed to deliver high-quality glass smoking accessories at scale — consistently, efficiently, and on schedule.

Our Factory: Where Craft Meets Technology

Located in Hebei, China — the country’s glass manufacturing base — our factory is equipped with both traditional hand-blowing workshops and modern processing lines.

This combination allows us to produce large volumes of hand-blown glass bongs, pipes, and glass bong accessories while maintaining the precision and detail of true craftsmanship.

Our Factory: Where Craft Meets Technology

Ensure Quality From The Starting Line

We start with high-grade borosilicate glass, known for its clarity and heat resistance.

Only certified materials enter our production line to guarantee strength and purity.

Adhere To The Art Of Handcraft

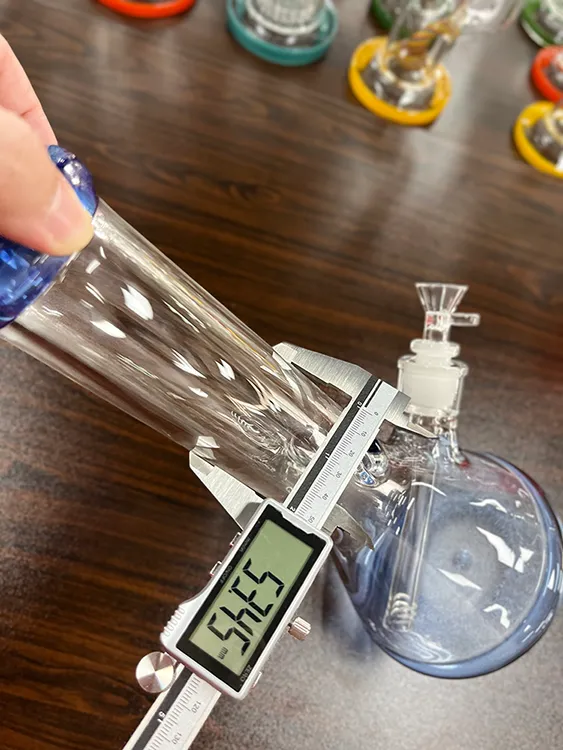

Our artisans use precise flame control to form each piece.

Whether it’s a classic beaker bong or a complex recycler, every curve and joint is shaped by hand to ensure smooth airflow and consistent wall thickness.

The Key To Both Durability And Good Looks

Each product passes through annealing kilns for several hours to remove internal stress.

This process ensures every glass piece remains durable, heat-resistant, and less likely to crack under temperature change.

Going A Step Further On The Original Basis

After cooling, products go through grinding, polishing, and sandblasting to achieve a clean, refined surface.

Custom logos, decals, or colored accents are then added per client requirement.

Give Customers The Best Experience

Our QC team performs 100% inspection on shape, transparency, balance, and joint fitting.

Every product is safely packed with foam inserts and double-layer cartons to withstand long-distance transport.

Quality Assurance System

Our commitment to quality goes beyond inspection — it’s built into our daily operations.

We maintain strict internal standards for temperature control, uniform thickness, and clarity. Each batch is tested to ensure:

- Smooth airflow performance

- Heat and impact resistance

- No leaks, cracks, or bubbles

Our philosophy is simple: “Only the best make premium.”

Smart Logistics and Fast Delivery

To support our global B2B clients, we operate a 5,000㎡ warehouse in Dongguan, southern China.

This allows us to store popular items, prepare mixed orders, and ship quickly from ready stock.

We also maintain strong partnerships with professional logistics and customs agents, enabling:

- Fast international shipping (as quick as 10 days to the U.S.)

- Flexible shipping methods – sea, air, or combined transport

- DDP service, reliable customs clearance for regulated markets

Our integrated logistics network ensures that every customer receives products on time and in perfect condition.

Craftsmanship You Can Trust

Partner with EG Glass and turn a reliable supply into a competitive advantage.

Explore our catalog, discuss your needs, and discover how we can grow your business with premium glass craftsmanship.